Circuit Board Box

The second major component of the PiggyBackTrim is the box that houses the joystick circuit board.

We will make our box out of a note card. Strength will not be an issue as we will reinforce it with some carbon fiber and the entire unit will be fiberglassed.

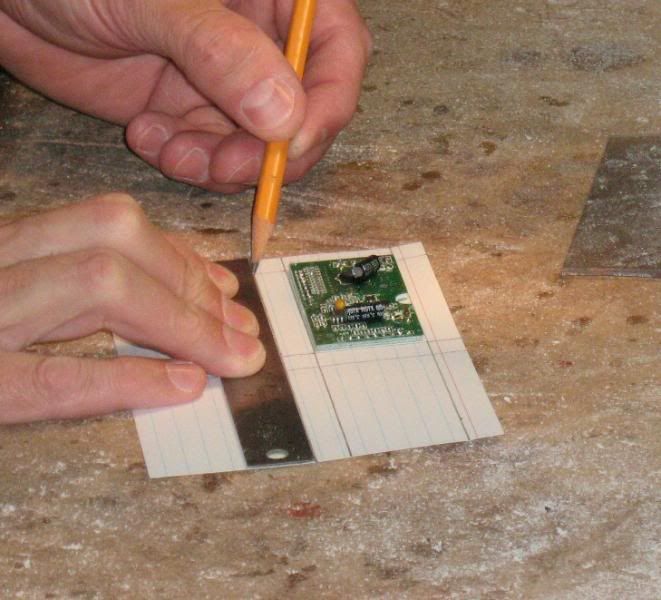

Begin by outlining the circuit board on a note card and make the walls tall enough to clear the height of the tallest object on the CB.

Cut the corners out and fold up all the edges and glue them together to form a box.

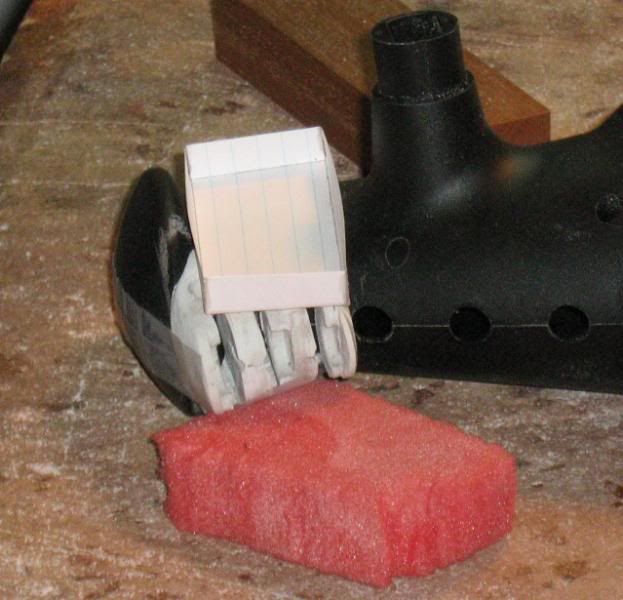

Next, mix up some epoxy putty and lay down a foundation for mounting the circuit box.

Mash the box down into the putty checking the alignment so you get it set squarely under the throttle. The rear edge of the box should be almost aligned with the edge of the wheel pot housing.

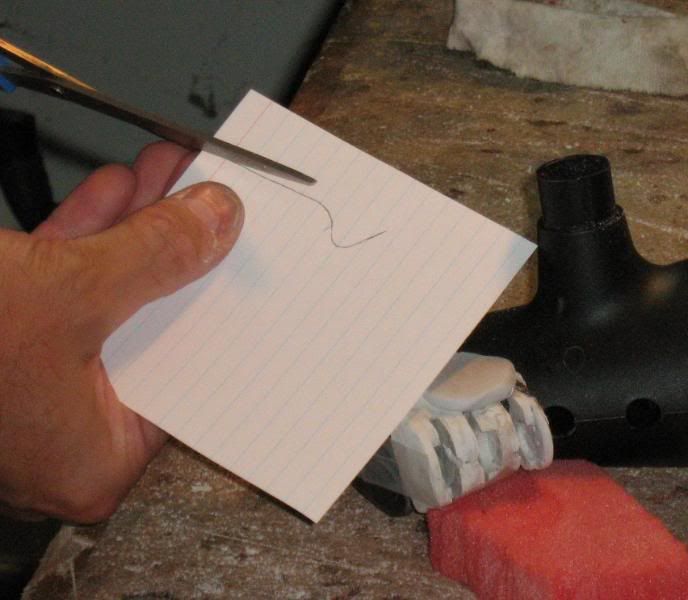

We want to build a flange on the front portion of the box because the Velcro strap will need a place to attach plus we want to make sure there is sufficient strength to support the tension of pulling the Velcro tight. Here I'm using a pattern matching tool to copy the shape of the PT at the forward edge of the circuit box.

Once we get the shape, cut out another piece of note card stock to make a leading edge that will be glued on the front of the circuit box.

Glue the leading edge in place on the circuit box.

We're now ready to glue the circuit box into position.

Use some putty to build up an area to support the wheel pot cover plate.

Using a ruler, shape the putty to form the base where the wheel pot cover plate can seat squarely.

Finally, form the front flange following the shape of the PT. Grease the throttle good first to make sure the putty doesn't stick to it.

Glue a small piece of wood on the rear portion of the circuit box. This will provide a place to drill a hole for the USB cable. After a little sanding, the unit is now ready for fiberglassing.

I'm using a hack saw blade to get the flange good and square. Round off the front nicely just to give it a pleasant look. The Velcro "hooks" will be attached to the face of this flange.

Glue a small piece of wood on the rear portion of the circuit box. This will provide a place to drill a hole for the USB cable. After a little sanding, the unit is now ready for fiberglassing.