Fourth and final day

Now, the finish work.

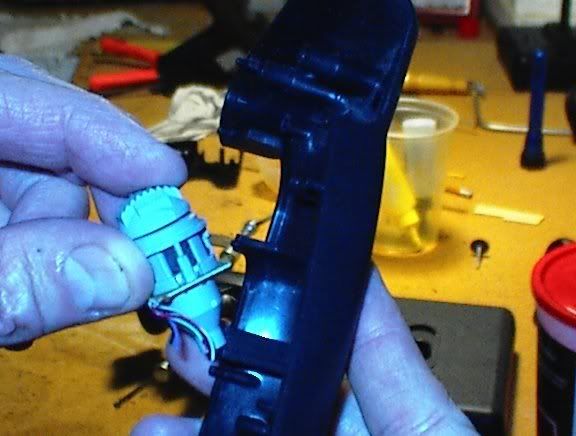

The biggest stress point is the stem of the throttle. If you're like me, you have a tendency to use your throttle as an arm rest while reading manuals, etc. The last thing I want is to break the stem off. Here, I'm using a radio control airplane builders secret weapon: carbon fiber. It looks like hair and when painted onto a surface with epoxy, it becomes like metal, except without the weight. It's great stuff. I once ran an airplane into the ground (radio failure) from about 400 feet at full speed. The plane was completely destroyed except for the places where I had painted in carbon fiber.

Next, I apply some fiberglass cloth over the carbon fiber and in the other areas where I've glued a piece on, e.g. the FS nose, throttle stem, patched hole on top of throttle.

After the fiberglass dries, I sand it with some very rough sandpaper and bring out another secret weapon. Being from East Tennessee, this stuff is as common as milk and bread. In fact, you find this stuff on the shelf in the grocery store right there beside the bread! What am I referring to? You got it: Bondo! Known by non-southerners as Auto Body Filler. As a kid, I used to get this stuff in my stocking at Christmas time!

Once the Bondo has been applied everywhere there are gaps and pits, everything gets sanded good and is now ready for a paint primer.

Applying the primer. One of the main reasons I'm doing this is that the primer brings out imperfections in the finish. I have been known to apply primer three or four times as I putty over pits and scratches and re-prime.

The construction of the FlightStick and Pro Throttle handles is now complete.

Finally, I apply three coats of a great product I found for painting controller handles. It is Rust-Oleum Textured Finish. It leaves the distinctive sandy textured finish that controllers tend to have. I used this stuff on my controllers about three years ago and there is no sign of it wearing off and it has never rubbed off on my hands. It is really a remarkable product.

Hope you enjoyed the little tutorial. Also, I hope some of you will give this a try. It's really not that hard if you just take your time and work sequentially and carefully.

Thanks for following along.

-mark